Call Us

+86-13486669457Inspect Hitch Components: Conduct a comprehensive visual examination of every element constituting the 3-point hitch assembly. Begin with a meticulous inspection of the hitch arms, scrutinizing them for any signs of wear, deformation, or corrosion. Next, closely examine the hydraulic cylinders, paying careful attention to the seals, rods, and mounting brackets. Inspect the linkages connecting the hitch arms to the tractor, checking for tightness, proper alignment, and any indications of damage or excessive play. Evaluate the attachment points where implements are connected to the hitch, ensuring they are intact and securely fastened. Utilize appropriate tools such as flashlights, mirrors, and inspection mirrors to thoroughly assess all components, including those that may be challenging to access.

Check Hydraulic Fluid Level: Access the tractor's hydraulic reservoir and meticulously gauge the fluid level using a dipstick or sight glass, adhering to safety protocols to prevent contamination or spillage. If the fluid level falls below the recommended range specified by the manufacturer, meticulously ascertain the cause of the deficiency, which may include leaks, evaporation, or improper filling procedures. Thoroughly examine the hydraulic system for any indications of leaks, inspecting hydraulic hoses, fittings, and connections with meticulous attention to detail. Utilize appropriate containment measures to capture and dispose of any spilled hydraulic fluid in accordance with environmental regulations and best practices.

Check Hydraulic Hoses and Connections: Conduct a systematic examination of all hydraulic hoses, meticulously tracing their entire length to identify any signs of abrasion, cuts, bulges, or other damage. Pay meticulous attention to hose fittings, connectors, and couplings, ensuring they are securely fastened and free from leaks. Utilize appropriate tools such as inspection mirrors, magnifying glasses, and hydraulic pressure gauges to detect even the slightest indications of hydraulic fluid leakage. Employ standardized testing procedures, such as hydraulic pressure testing or dye penetration testing, to pinpoint elusive leaks and confirm the integrity of hydraulic system components.

Inspect Hitch Pins and Bushings: Perform a detailed examination of all hitch pins, bushings, and associated hardware, utilizing precision measuring tools to assess their dimensional accuracy and integrity. Employ non-destructive testing techniques, such as magnetic particle inspection or ultrasonic testing, to detect hidden defects or material degradation within hitch pins and bushings. Implement proactive maintenance strategies, such as lubrication schedules and corrosion prevention treatments, to extend the service life of hitch pins and bushings and minimize the risk of premature failure.

Check Ground and Terrain: Conduct a comprehensive site survey of the operating environment to assess ground conditions, terrain topology, and potential obstacles that may affect the performance of the 3-point hitch assembly. Utilize specialized surveying equipment, such as laser levels, GPS receivers, or terrain mapping drones, to generate detailed topographic maps and elevation models of the work area. Analyze the impact of soil properties, moisture content, and compaction levels on the stability and traction of agricultural machinery, including tractors equipped with 3-point hitch assemblies. Implement site-specific mitigation measures, such as soil conditioning treatments, terracing, or drainage improvements, to minimize the adverse effects of uneven terrain on hitch operation and optimize overall productivity.

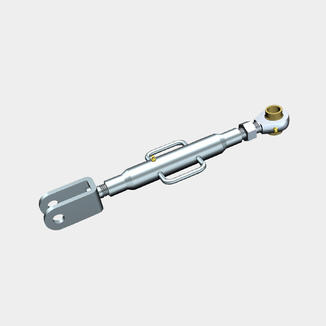

Hydraulic Forged Tractor Top-Link With Rod End For 3 Point Linkage

中文简体

中文简体

English

English