Call Us

+86-13486669457Visual Inspection: Employ a comprehensive visual assessment encompassing all surfaces of the turnbuckle jaw ends. Utilize adequate lighting conditions and consider employing magnification tools, such as magnifying lenses or microscopes, to meticulously scrutinize every inch for any discernible signs of wear, including but not limited to, surface deformations, micro-cracks, pitting, or any irregularities in texture. Discern any areas exhibiting abnormal discoloration, which may signify the onset of corrosion or exposure to corrosive agents. Segregate observed anomalies based on severity and location for further analysis and remedial action.

Check for Corrosion: Corrosion poses a substantial threat to the structural integrity of turnbuckle jaw ends. Conduct a meticulous examination of all surfaces, paying particular attention to regions prone to corrosion, such as crevices, weld joints, or areas exposed to harsh environmental conditions. Utilize corrosion detection methods, such as visual inspection, ultrasonic testing, or eddy current testing, to identify both visible and hidden signs of corrosion. Categorize identified corrosion based on severity, type, and extent to facilitate appropriate remediation strategies, including surface treatment, corrosion prevention coatings, or component replacement.

Inspect Threads: Thoroughly inspect the threads of the turnbuckle jaw ends for any indications of wear, abrasion, stripping, or galling. Employ precision measuring instruments, such as thread gauges or micrometers, to assess thread dimensions and verify conformity to specified tolerances. Employ non-destructive testing techniques, such as magnetic particle inspection or dye penetrant testing, to detect subsurface defects or cracks that may compromise thread integrity. Differentiate between cosmetic imperfections and critical defects to prioritize corrective actions, including thread repair, rethreading, or replacement of the turnbuckle assembly.

Evaluate Fittings: Examine the attachment fittings of the turnbuckle jaw ends meticulously to identify any signs of mechanical damage, fatigue, or material degradation. Employ advanced inspection techniques, such as phased array ultrasonic testing or computed tomography scanning, to detect internal defects or anomalies within the fittings. Analyze stress concentration areas and fatigue-prone regions for early signs of crack initiation or propagation. Prioritize inspection of load-bearing interfaces and weld joints for indications of weld defects, including porosity, lack of fusion, or weld discontinuities.

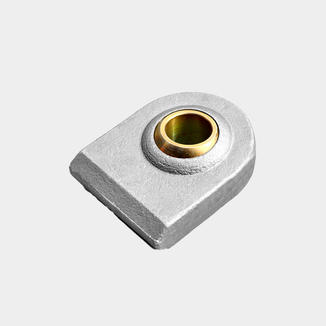

Inspect Pin Holes: If the turnbuckle jaw ends incorporate pins or locking mechanisms, scrutinize the pin holes meticulously for signs of wear, elongation, or distortion. Utilize high-resolution imaging techniques, such as optical microscopy or scanning electron microscopy, to visualize surface morphology and identify microscopic defects or irregularities. Employ non-destructive testing methodologies, such as ultrasonic flaw detection or radiographic inspection, to evaluate pin hole integrity and detect internal flaws. Analyze material properties and metallurgical characteristics to assess susceptibility to corrosion, fatigue, or mechanical stress.

Check for Looseness: Conduct a comprehensive assessment of the turnbuckle jaw ends to detect any indications of loose connections or inadequate fastening. Employ torque wrenches or tension measuring devices to quantify preload forces and verify adherence to prescribed torque specifications. Assess fastener condition and thread engagement using visual inspection or tactile feedback to detect signs of thread wear, stripping, or deformation. Employ mechanical locking devices or secondary retention mechanisms to mitigate the risk of fastener loosening or disengagement under operational loads.

Turnbuckle DIN 1478 Jaw&Jaw Assembly

中文简体

中文简体

English

English