Call Us

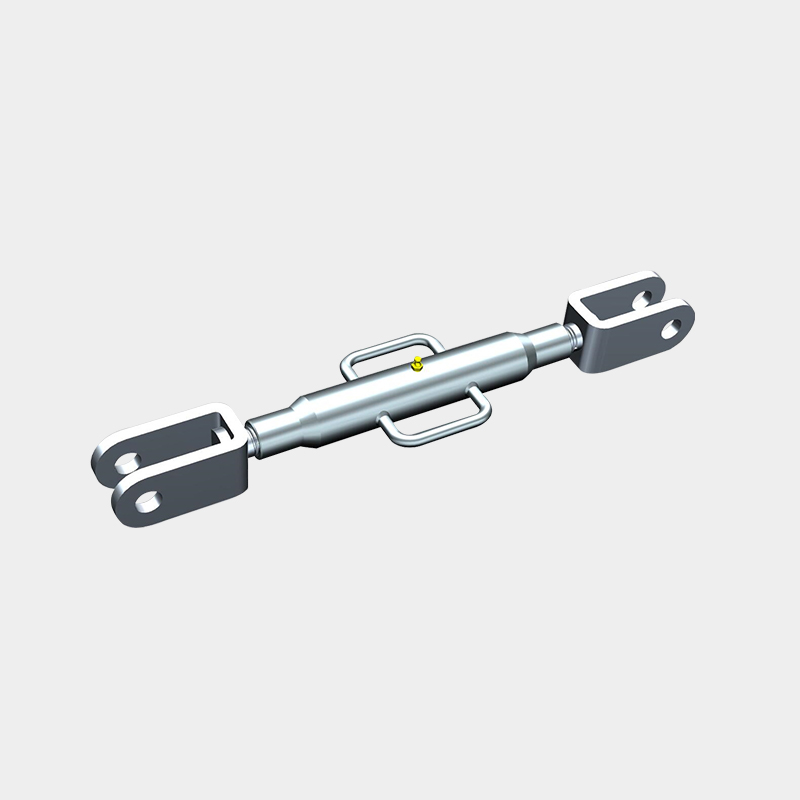

+86-13486669457Inspect the Top Link: Conduct a comprehensive inspection of the tractor top link before making any adjustments. Check all components, including the adjustment threads, pins, hydraulic cylinders (if applicable), and locking mechanisms. Ensure there are no signs of wear, corrosion, or damage that could compromise the safety and functionality of the tractor top link during operation. Lubricate all moving parts to prevent premature wear and ensure smooth adjustments.

Attach the Implement: Securely attach the agricultural implement to the tractor's three-point hitch system according to the our guidelines. Clean all hitch points and ensure they are aligned correctly. Proper alignment prevents stress on the tractor top link and promotes even weight distribution across the implement during operation.

Set the Tractor to Operating Conditions: Park the tractor on a level surface and lower the implement to the operating position. Ensure the tractor is in neutral gear and engage the parking brake to prevent unintended movement during adjustment. Lowering the implement allows you to accurately assess its position and make necessary adjustments to achieve optimal weight distribution.

Adjust the Length: Use the adjustable features of the tractor top link to modify its length. Adjusting the length changes the distance between the tractor and the implement, thereby altering the angle at which the implement engages with the ground. Consult the tractor and implement manuals to determine the recommended length based on the weight of the implement, its type (such as a plow, harrow, or mower), and the desired operational angle for efficient performance.

Achieve Proper Angle: Aim to set the tractor top link so that the implement is level or slightly angled downward toward the ground when viewed from the side. This positioning ensures proper ground contact and promotes even weight distribution across the implement. Avoid setting the implement at too steep an angle, which can strain the tractor's hydraulic system and reduce overall operational efficiency.

Check for Even Weight Distribution: After adjusting the tractor top link, visually inspect the implement from multiple angles. Verify that it is positioned evenly and securely supported by the tractor top link. Uneven weight distribution can lead to premature wear on components, reduced operational efficiency, and potential safety hazards during field operations.

Test and Fine-tune: Conduct a brief operational test by moving the tractor and implement a short distance on level ground. Observe how the tractor handles the load and how the implement interacts with the soil surface. Listen for any unusual noises or vibrations that may indicate the need for further adjustments.

Secure Adjustments: Once satisfied with the adjustments, securely lock any adjustment mechanisms or locking pins on the tractor top link. This step prevents unintended changes during operation and ensures the implement remains securely attached to the tractor, maintaining consistent performance in the field.

Monitor and Maintain: Regularly monitor the tractor top link and its adjustments during use. Factors such as soil conditions, terrain variations, and operational loads can affect the performance of the implement and the stability of the tractor. Periodically check and readjust the tractor top link as needed to maintain optimal weight distribution, operational efficiency, and safety during agricultural tasks.

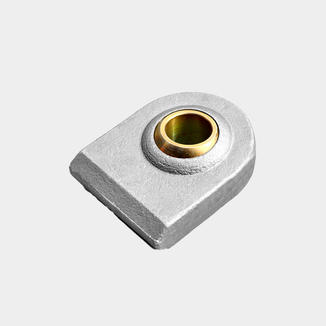

Lift Arm Leveling Assembly Tractor Lift Arm

中文简体

中文简体

English

English