Call Us

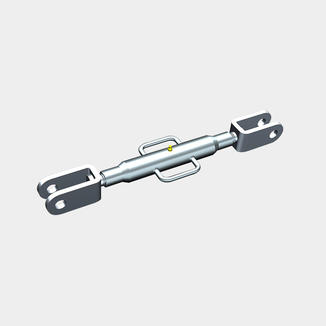

+86-13486669457The internal geometry of SAE Split Flange Halves is carefully engineered to ensure that the fluid experiences minimal resistance during transit. These flanges are designed to match the size and shape of the piping or hose system they connect to, minimizing abrupt changes in cross-sectional area that could disrupt the flow. The interior of the flanges is often carefully contoured to maintain laminar flow conditions, thereby avoiding areas where turbulence could form. By minimizing bottlenecks and constrictions, these flanges help preserve the flow characteristics of the fluid, ensuring that the system operates with maximum efficiency, especially at high flow rates. This optimized design helps to prevent excess friction, which could otherwise cause a drop in pressure or temperature variations, which are detrimental to system performance.

The quality of the internal surface finish within SAE Split Flange Halves plays a pivotal role in maintaining smooth fluid flow. Through advanced precision machining techniques such as CNC turning or grinding, the surfaces of these flanges are crafted to tight tolerances with minimal surface roughness. A smooth finish minimizes the frictional forces that oppose the flow of fluid, preventing the formation of turbulence. When the surfaces are rough or uneven, flow disturbances occur as the fluid experiences variable pressure zones and eddies. These disturbances can significantly reduce the system’s efficiency and even lead to operational failures. The precise manufacturing of SAE Split Flange Halves ensures that the flow remains stable, the pressure is maintained, and energy losses due to friction are minimized, resulting in better overall system performance.

The design of the SAE Split Flange Halves ensures that when they are assembled, they form a uniform, seamless connection. The split flange halves are crafted so that, once installed, they create a smooth internal transition between the piping and the flange, minimizing any irregularities that could disrupt the flow path. The even distribution of fluid pressure and velocity across the entire cross-section of the flange helps eliminate any potential hotspots or areas where turbulence might develop. By ensuring that the flow path remains continuous and symmetric, the split design helps maintain fluid dynamics at optimal levels, reducing unnecessary energy consumption and preventing fluid velocity fluctuations that could impact system performance. This balanced distribution is crucial for applications requiring high-flow rates, such as hydraulic systems or industrial fluid transport.

SAE Split Flange Halves are designed to work seamlessly with a wide range of hoses, pipes, and fittings, making them highly adaptable to diverse system configurations. The dimensions of the flanges are standardized to match the nominal sizes of hydraulic and pneumatic components, ensuring a proper fit that minimizes the chances of flow restrictions due to mismatches. Compatibility with standard components allows these flanges to be easily integrated into both new systems and retrofit applications without requiring custom modifications or adaptations. The smooth transition between the flange and the hose or pipe reduces the chances of localized flow disruptions, which can lead to turbulence or efficiency losses.

The materials used in the manufacturing of SAE Split Flange Halves are selected for their strength, durability, and ability to withstand the high-pressure conditions typical in fluid systems. Materials such as carbon steel, stainless steel, or alloy steels are commonly used for their resistance to deformation, corrosion, and wear. The structural integrity of the flanges ensures that they do not bend or warp under the operational stresses of high-flow, high-pressure systems. If the flange were to deform, it could cause significant disruptions in the flow path, such as constriction or misalignment of the flow direction.

中文简体

中文简体

English

English